One Guide, One Bit, One Setup…

It’s that Easy

The FMT Pro has several features that make mortise & tenon joints quick and easy to rout. For the serious hobbyist or small shop professional, there is simply no faster or more accurate method. With one guide, one bit and one setup, the FMT Pro can rout both the mortise and matching tenon in just 60 seconds. Read on to learn more.

Key Components and Construction

The movable table positions the extended sight precisely over the marked workpiece. To rout the joint, the sub-base guide pins slide in the table's pin track and around or in the center slot of the inserted joint guide. Teflon pads on both the table and sub-base make routing incredibly smooth.

Joint guides snap easily into the guide recess.

Aligning the table to the layout lines with the sight is incredibly precise.

For multiple joints, limit stops (red arrows) and posts (white arrows) are used to position the table in set, repeatable positions.

If you want to rout a joint that’s wider or narrower than the standard guide size, or if you don’t have the right guide on hand, you can use the table movement in conjunction with the limit stops to produce multiple size joints from a single guide. The 1″ and 2″ tenons shown opposite, were both routed using the same 1-1/2″ guide.

One joint guide can rout different joint sizes.

One joint guide can rout different joint sizes.Guides for Special Joints on the FMT Pro

Y-AXIS MORTISES

In instances when mortises

need to be routed at 90°

to the clamp plate, this

guide does the trick.

Learn more >

LOUVER DOORS

Make beautiful louver doors with

these left or right matching pairs

of guides.

Learn more >

SQUARE TENONS

Square tenons are often used

for replicating period furniture.

Learn more >

A Leigh brand 5/16" (8mm) HSS spiral upcut 1/2" shank bit is included with the FMT Pro. More bit sizes are available in HSS or solid carbide. Solid carbide bits are stiffer, rout cleaner and last longer than HSS bits. A bit set is available for savings over individual bits.

The universal sub-base is designed to fit virtually any router. Fitted with your router and a bit, the sub-base works in conjunction with the table to rout the mortises and tenons. Read on to learn about router compatibility and joint fit adjustment.

The two guide pins projecting from the universal sub-base steer the attached router in the right track of the table and in or around a guide in the left guide recess, to rout the joints.

The FMT Pro can accommodate most popular brand routers. It can only be used with plunge routers, and will not work with fixed-base routers. A router with a 1/2" collet is required to get the most from your jig.

FENCE ROD MOUNTING

Most routers attach to the sub-base using

two fence rods held in place by U-posts.

DIRECT SCREW MOUNTING

Some routers attach directly to the

sub-base using two or three of the

included Leigh screws.

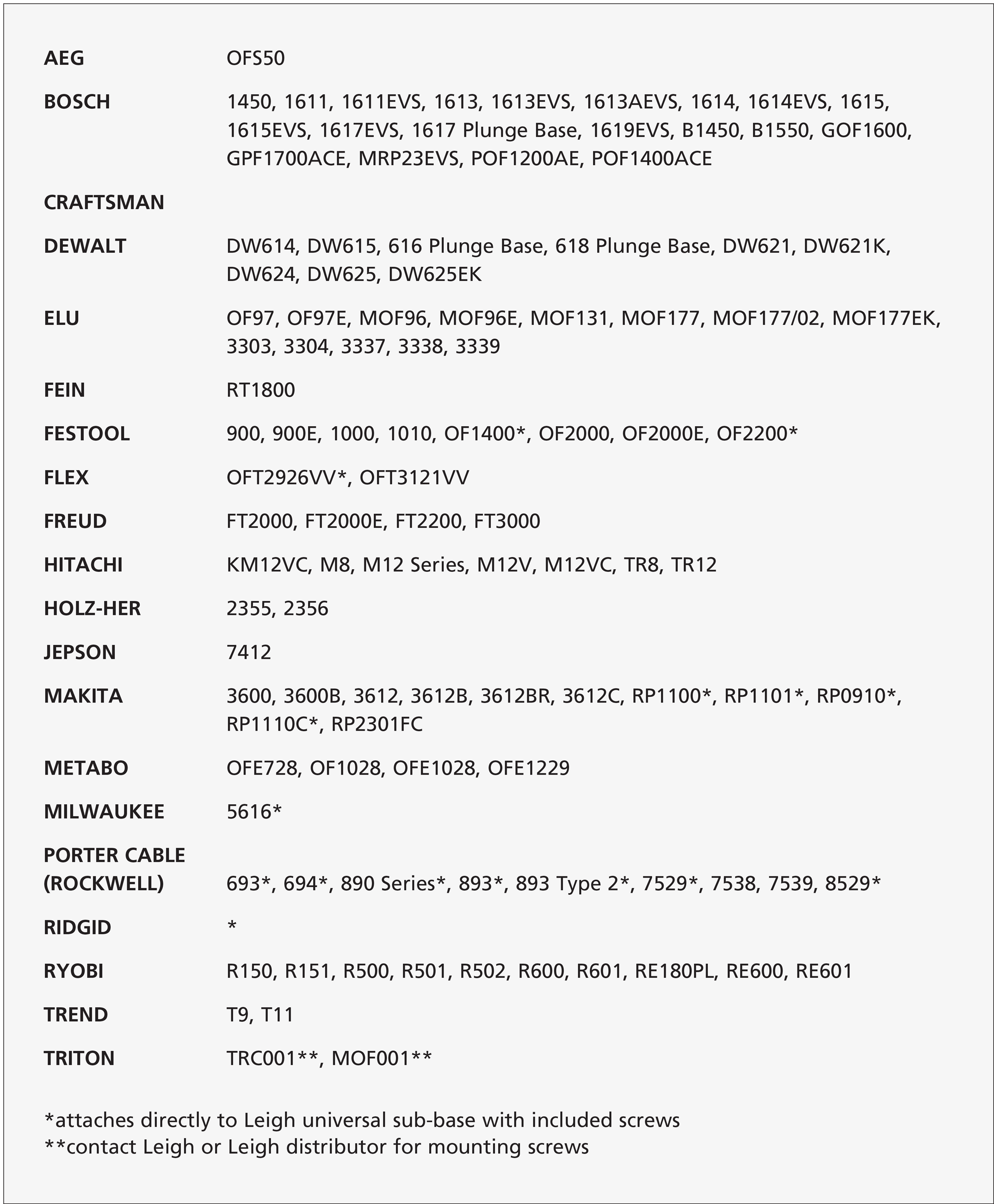

The following is a list of routers compatible with the FMT Pro. It is updated on a regular basis as new routers are available. If your router is not listed, a quick toll free call to Technical Support, 800-663-8932 in USA/Canada, is all that is necessary to determine a mounting solution.

The left guide pin projecting from the universal sub-base does more than steer the router — it's adjustable up or down in 0.001"(0.025mm) increments for perfect joint fit.

Turning the tapered left guide pin knob up against the tapered guide produces a smaller tenon and larger mortise, just as turning it down produces a larger tenon and a smaller mortise. Each 1/8 of a turn adjusts the glue line fit by 0.001" (0.025mm).

Mortise and tenon workpieces are securely mounted onto the jig's machined clamp plate with Leigh's heavy duty cam-action speed clamps. An adjustable side stop fence provides accurate tenon board positioning and a mortise steady.

CLAMPS Workpieces are held securely against the clamp plate by 3" Cam-action Speed Clamps. Quick to mount in the T-slots and keyholes, they are extremely strong and easily adjustable.

CLAMP PLATE SURFACE Workpieces are secured in place against the clamp plate's machined, non-marring, textured surface.

ANGLED CLAMP PLATE The clamp plate can be tilted

up to 30° for angled joints.

TENON POSITIONING The adjustable side stop fence provides accurate tenon workpiece positioning. The short end acts as a T-square against the clamp plate edge.

MORTISE STEADY The side stop fence provides additional support for smaller mortise workpieces.

ANGLED SIDE STOP The side stop fence (secured to clamp plate in reverse position) can be angled up to 45° for angled joints.

The FMT Pro makes chair joints easy to rout. Its unique design with adjustable side stop and tilting clamp plate makes for simple setup of multiple angled joints.

Chairs are often made using single and compound angled tenons (mortises are not angled).

SINGLE ANGLED TENON (using angled clamp plate).

SINGLE ANGLED TENON (using angled side stop).

COMPOUND ANGLED TENON (using angled clamp plate and angled side stop).

For an even stronger mortise & tenon joint, double, quadruple, or even triple joints are remarkably simple to make with the FMT Pro and can be used in workpiece thicknesses up to 3" x 5-1/2" (76 x 140mm). Their strength is largely due to the greater glue surface they provide. Simple table movements using limit stops provide accurate positioning of each mortise and tenon.

Double in line mortise & tenons add strength to table rails.

For multiple joints, limit stops (red arrows) and posts (white arrows) are used to limit the travel of the table.

Small and Miniature Joints

Due to the accuracy of the FMT Pro, it can rout joints not only smaller than 1/4" (6mm), but so tiny they're almost beyond belief — all with the same easy setup and adjustable fit you expect in larger joints. For more info, see How To page.

The matchsticks feature mortise & tenon joint sizes of .040" x .095" and .013" x .053"! The smallest mortise & tenon was routed with 1/64" (0.4mm) mortise and 31/64" (12.3mm) tenon machine tool bits. These matchstick joints actually creak when assembling! CNC machine cutters were used to make these incredible joints.

The 7-1/2" (190.5mm) ebony and holly ladder leaning against a 1/2" x 5" (12 x 127 mm) tenon has ebony wedged tenons 1/16" x 1/8" (1.59 x 3mm).

Miniature furniture parts such as small cabinet door frames, doll house architecture and furniture, and very accurate miniatures all call for mortises and tenons as narrow as 1/8" (3.2mm) or less.

The FMT Pro is ideally suited for production routing. Using a larger bit to rout the tenons can speed up production dramatically. For more info see the How To page

The FMT Pro comes with two bars for attaching shop-made outrigger beams to the jig. Outrigger beams increase the capacity, speed and accuracy of the Leigh FMT Pro by enabling successive mortises on one workpiece and repeatable mortises on multiple workpieces.

The built-in vacuum box has a tilting 1-3/8" dust collection port that can be stepped up to 2-1/2" or down to 1" with the two included adaptors.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Through Joints

Massive Joints

Simple Angled Joints

Compound Angled Joints

Floating Tenons

Miniature Joints

Louver Door Joints (optional)

Square Tenon Joints (optional)

Y-Axis Mortise Joints (optional)

Jig Body, Clamp Plate, Table with guide track

Universal Sub-base (attaches to virtually any

plunge router) Includes router hold-down

rods and related hardware

Outrigger Bars with mounting hardware

Jig Mounting Hardware

1/8" Ball End Hex Screwdriver

Square Drive Screwdriver (No.2 Robertson)

5/64" Hex key (for sight adjustment and Festool router attachment

Five 5/16" Joint Guides and Stand

(8 x 15, 20, 25, 30, 35 and 40mm), which can make over 21

(24 metric) sizes of mortise & tenon joints

Two Cam-action Speed Clamps

5/16" (8mm) HSS spiral upcut bit with 1/2" shank

Centering mandrels, Inch (1/4", 1/2") Metric (8mm, 12mm)

Adjustable Side Stop Fence

Vacuum Box with hose adaptors for 2-1/2" and 1" hose sizes

Fully illustrated user guide.

Instructional videos are available online at Support/ Instructional Videos and User Guides page

Warranty/Registration Card

The following router bits and guides increase versatility. Available in accessory kits for greater savings.

High Speed Steel Bits, 8 additional

Guides, 16 additional

Louver Door Guides

Square Tenon Guides

Y-Axis (Right Angle) Mortise Guides

Learn more

Leigh Mortise & Tenon Jig Comparison

See comparison overview

See detailed comparison chart